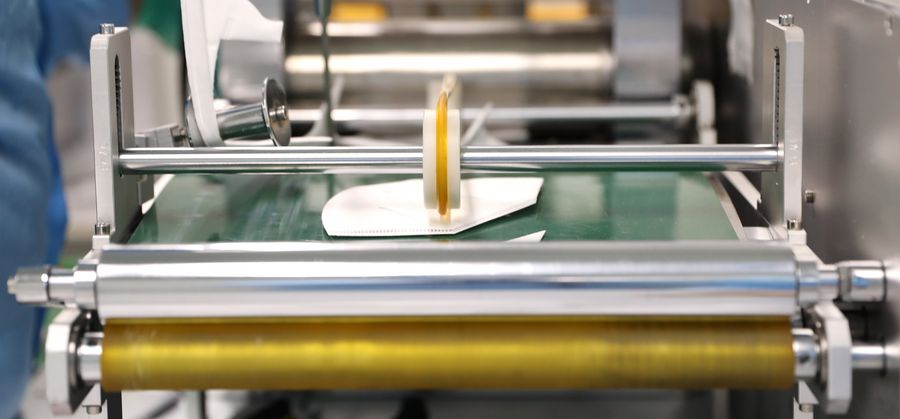

Workers make masks at a medical technology company in Binzhou High-tech Industry Development Zone in Binzhou City, east China's Shandong Province, Feb. 8, 2020. (Photo by Chu Baorui/Xinhua)

Many factories across the country have suspended their own production and turned to manufacturing medical supplies to fill the demand gap amid the outbreak.

SHENYANG, Feb. 11 (Xinhua) -- A garment plant in Fushun, northeast China's Liaoning Province, recently purchased 10 tonnes of medical nonwoven fabric and began producing masks.

"About 20 workers at the plant can produce over 5,000 masks a day," said the head of the company. These masks are expected to be delivered to medics at the front lines of the battle against the novel coronavirus.

Many factories across the country have suspended their own production and turned to manufacturing medical supplies to fill the demand gap amid the outbreak.

Data from the National Development and Reform Commission (NDRC), the country's top economic planner, showed China produces about half of the world's masks with a daily output of 20 million. But that is still insufficient to meet the exploding demand.

Even global stocks of personal protection equipment are raising red flags, according to the World Health Organization.

Since masks are not a complicated product and can be manufactured by an existing production line without much retrofitting, China has encouraged factories to join the production of protective masks to increase supply.

On Feb. 6, Liuzhou-based auto maker SGMW in south China's Guangxi Zhuang Autonomous Region announced that it will revamp 14 production lines to produce N95 and other surgical masks with a daily output expected to reach more than 1.7 million.

A Foxconn plant also began trial-producing masks on Feb. 5 and is applying for product qualification certification.

Photo shows a medical N95 mask on a production line of a mask production company in Shenyang, capital of northeast China's Liaoning Province, Feb. 8, 2020. (Xinhua/Yao Jianfeng)

Data from Tianyancha.com, an online database query platform, showed over 3,000 companies in China have added "masks, protective clothing, disinfectant, thermometers and medical equipment" to their business scope between Jan. 1 and Feb. 7.

Many local governments have also rolled out supportive policies such as fund subsidies, fast approval, financing and manpower support to help factories switch production.

Five years ago, a medical science and technology company in Shenyang, capital of northeast China's Liaoning Province, closed its production line for surgical masks due to poor management. After learning that the company still kept the equipment and factory, the local government helped it re-register its business license in a day and allocated funds to help resume production within days.

"We now can produce 20,000 medical protective masks a day and the daily output is estimated to reach 220,000 when a new line enters production in about 20 days," said Gao Wei, the company's general manager.

Some manufacturers expressed concern over overcapacity after the epidemic. In response, Lian Weiliang, deputy director of the NDRC, said the government would be the ultimate buyer if the market could not consume all the products.

More than 76 percent of mask production capacity in China's 22 provincial regions had been resumed by Monday, according to Cong Liang, secretary-general of the NDRC. ■